An innovation that could dramatically increase train loading and unloading capacity at ports around the world.

Transporting and distributing commodities has remained virtually unchanged since the unit train inception in the 1960s. At origin and destination facilities, balloon and loop tracks are used to load and unload products. While present-day loop tracks can accommodate a single unit train, they cannot efficiently process multiple unit trains at a high rate. The throat area -where trains enter and exit—clogs because trains arriving, departing or being processed cross the same tracks in this area.

The only solution, until now, has been to increase the number of tracks and facility size. A first in the world, the Infinity Loop Rail Design solves the question of how to process multiple unit trains at a high-throughput facility while not impacting processing throughput or mainline traffic. At the first site, this seemed impossible—even with continuous operational throughput, there was not enough time in a day to process the desired number of trains.

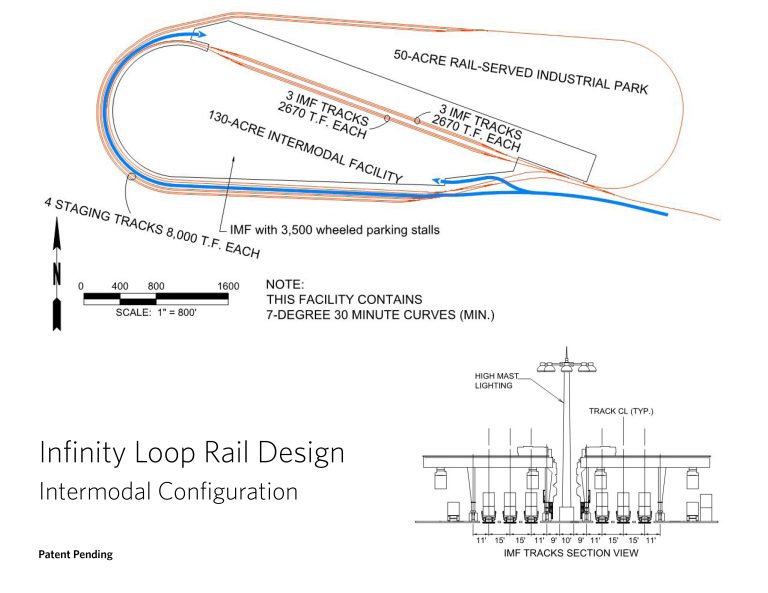

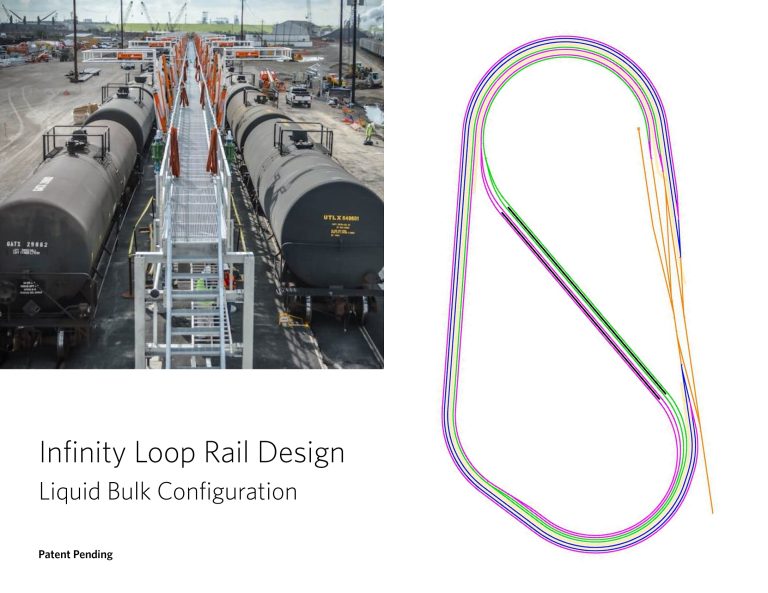

To create the solution, they laid out an eight-track staging yard in front of an unloading balloon track. Wrapping the staging tracks, each capable of holding a unit train, around the balloon minimized the footprint and resembled an “infinity” symbol—securing the design name and forming an endless loop design that allows multiple unit trains to enter their the facility without conflicting with other trains during loading or unloading.

Unit trains now can be loaded or unloaded in succession, following the same path from staging onto the balloon track, through the loading/unloading facility, then depart to the mainline or return to staging without crossing the path of the next train.

An innovation this monumental comes around about once every century. The reduced delays and increased throughput will create operational efficiencies that effect commodity prices. The design also allows facilities to operate more densely on their footprint. Multiple facilities and balloon tracks can be placed within the Infinity Loop, significantly increasing land use density and allowing companies to share loop staging tracks without confliction.

Moreover, the loop designs number of staging tracks is essentially unlimited with minimal operational impacts and only incremental cost increases.

A small Infinity Loop is being constructed at the Port of Vancouver, British Columbia. This Infinity Loop design will allow three 134-car trains to move directly to the port, unload and return to the grain shippers for another load—one right after the other. This will cut the unloading/processing cycle time up to half while eliminating car shunting and engine revving while providing space for inspection vehicles and bad-order set-out tracks.

Historically, intermodal shipping and receiving facilities were located near mainline tracks and unencumbered by grade crossings. The new design allows them to be located anywhere and their shape does not require specific land configurations or grade separations.

As the design moves from concept to implementation, the Infinity Loop Rail Design will monumentally impact shipping, receiving, operating costs, and maintenance of port and rail facilities throughout the world.

Sorry, no records were found. Please adjust your search criteria and try again.

Sorry, unable to load the Maps API.

HDR